LANGUAGE OF LEAN

Kanban

The material in the Kanban System is exclusively oriented to the consumption of your production process.

In this article we want to talk about another classic from Lean Management Kanban or the so called Pull System.

The word Kanban itself has its roots in the Chinese Japanese language and means card, label or sticker. In industrial manufacturing planning systems or general in logistics control Kanban describes a replenishment system for consumed parts according to the amount used steered by cards that give the signal following the Pull Principle.

The material in the Kanban System is exclusively oriented to the consumption of your production process. The cards are a key element of this kind of control system and provide proper information transfer. Kanban control loops from the work station of flexible production control and serves to smooth material flow through your inbound or even outbound logistics. In addition Kanban serves you to implement a sustainable reduction of material stocks, increases the ability to deliver and saves you pure cash.

In an ideal world Kanban would control your entire value chain from the supplier to the end customer. In this way you would have installed an complete smooth supply chain with almost no chance of interruption and massive stocks. And now comes the but – to steer production with Kanban – a continuous monitoring is required for a smooth material supply. To make it short: it requires discipline from all involved parties along the supply chain.

Lets have a look to the development of Kanban.

The first Kanban System was developed by none other than Taiici Ohno (of course) at Toyota Motor in the 1940s. One of the main reasons for the implementation of Kanban was the low productivity and efficiency of Toyota compared to western competitors. With the Kanban System, Toyota achieved a significant change towards flexible and efficient production control that had a massive impact on productions output while at the same time reducing the costs for inventory in raw material, work in progress (WIP) and finished goods.

To give the complete picture it wasn’t implementing the Kanban system itself to drive the success of Toyota, there are other key factors that together where making the difference. Just to name Just in time as an example of key elements of the Toyota Production System. It is and always will be a combination of different methods and philosophy that brings you forward.

In the 1970s the Kanban Concept was adapted in the industry in the USA and Germany. As they haven’t known better, they pretty much copied the complete Toyota Production System (TPS) in order to get the principles running.

Pull or Kanban System

Either way you call it, the material flow is controlled by boxes or cards. Kanban Cards serving in a simple way all information needed to identify what parts are needed in what quantity at what place. The amount typically is defined by the replenishment time at the work station. With the so called two box principle you make sure that the operator never runs short on components. Nowadays there are also digital version of it called eKanban, but the principle behind is the same. The trigger of supply is the Kanban Card starting of the pull chain of material.

To use Kanban efficient, it is not suitable for all parts. Kanban is perfect for small parts with a small amount of variants and a consistent demand. For this reason, you’ll see Kanban Systems in the industry mostly used for C-Parts management. The rest of the components are steered with the support of MRP. Only in rare cases you find that even the supply of big components are controlled with the Kanban methodology.

One nice side effect with Kanban, you can set up the way you can steer your bottleneck. That means, when you have done a proper value stream analysis you know the capacity for your bottleneck and will only order what this process step can handle.

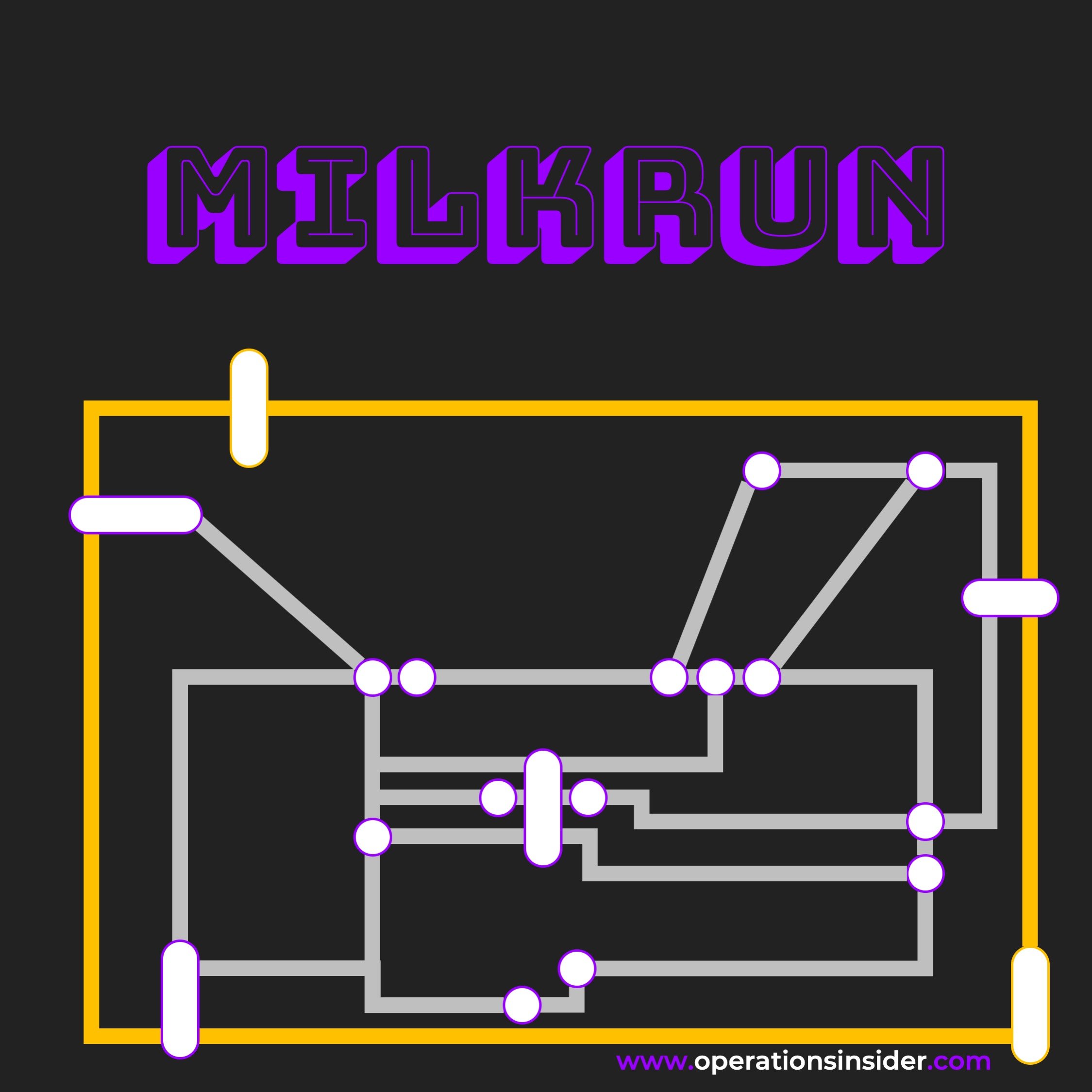

Milkrun

The Milkrun is the preset intralogistics concept to bring raw material, semi finished and finished goods to the place they belong at the time they are needed.

The Milkrun is the preset intralogistics concept to bring raw material, semi finished and finished goods to the place they belong at the time they are needed. The Mikrun is implemented based on existing consumption values, an internal supply cycle is defined in which deliveries on fixed routes are installed with specific times.

Based on these current consumption values, a logistic supply cycle is defined wherein raw material, semi and finished goods are delivered and picked up by a fixed route at a specific time. With this you will also optimize your intralogistics concept in general taking on action for a Milkrun concept.

So what is the idea behind the Milkrun concept.

The term Milkrun comes from the traditional milkman that was supplying milk to homes on a fixed route in a specific time. The milk delivery was based on the consumption of the households, by this only the amount of milk needed was delivered. Empty bottles have been picked up at the same time and brought back to the distribution center. So quite simple full bottle(s) delivered, empty bottle(s) picked up.

The cross company Milkrun

Nowadays the material management got a little bit more complex. Speaking in the external way of logistics a Milkrun is a supplier concept where customers ask for one or more shipping companies to manage different suppliers or customers on after the other in the form of a shipping cycle. In this way, goods and empty containers can be delivered and received at the same time without the need of centralization. The main goal is to have as less as possible empty trucks and at the same time being under full control of external material flow. Tours and deadlines are the guard rails on these cycles, reducing storage space is the nice to have side effect.

The benefits of the Milkrun concept

With installing a Milkrun you will be able to reduce shipping times, processing processes and therefore handling costs.

Just in Time and Just in Sequence deliveries are possible

Your planning is more structured as you will have fixed time frames

Less capital needed due to decreasing inventory/stock/WIP

You can integrate waste and empty container management

Increase of sustainability due to ecologically smarter transportation routes

Of course there are also some challenges with the Milkrun concept

Time consuming planning as quantity, duration, replenishment time, etc. needs to be considered

Processes and products need constant supply

Outbound Milkruns can be delayed by traffic or weather conditions

Economically relevant for larger business or higher demands of goods

Reliable supplier for products and transport needed

One last note for the internal Milkrun

Inbound the concept can be used in both ways, intralogistics and manufacturing. E.g. certain raw materials or semi-finished goods can be delivered on a regular basis to predefined workstations where the consumption can simply calculated. And on the fixed route the Mizusumashi can collect empty container and waste from production. This reduces internal ways of operators and guarantees a continuous supply of workstations. The next level would be to interlink all workstations or cells with your internal supply cycles to create an intralogistics flow, reducing the manual replenishment work. To find out what the Mizusumashi is just go here. In short: he/she is the guy who supllies goods on the shop floor in a structured process.

Stay Connected

Ad

We want information fast and in a nutshell. We from OI recommend Blinkist* - because it’s simply the best.

* = Affiliate Link